force position servo press

We have been committed to intelligent test equipment system, intelligent AI Internet system, intelligent manufacturing production line in one, set design, production, sales of excellent service providers, to provide customers with one-stop industrial products-intelligent system solutions.

Classification:

Key words:

Intelligent Test Equipment System | Intelligent Manufacturing Equipment System

Product Description

Overview

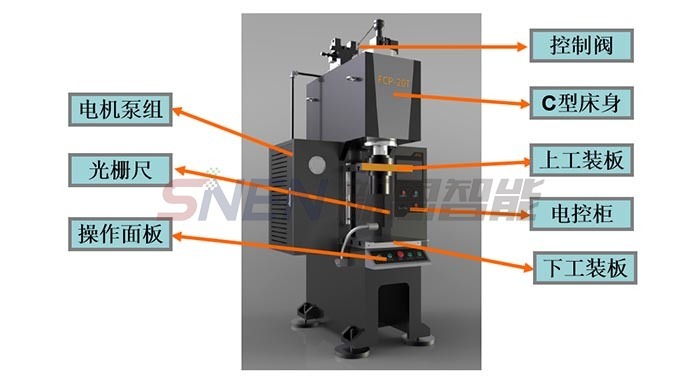

Force Position Servo Variable Frequency Press uses variable frequency hydraulic pressure as power to drive the oil cylinder. Grating ruler and PLC control form a full closed-loop position control. Compared with traditional mechanical travel switch control, the accuracy is greatly improved, and the position control accuracy can reach 0.1mm; The force sensor and PLC algorithm control can accurately control the pressure in time. Compared with the traditional force sensor, the pressure stability is greatly improved, and the pressure precision control can reach 0.05t.

equipment has the characteristics of flexibility and intelligence; it can control the forming process of parts and the precision of assembly process (including force control and displacement control). The

equipment adopts frequency conversion intelligent control technology, and automatically stands by

for 15 seconds without operation. Features

1, C- type bed, compact structure, strong rigidity and not easy to deform;

2, configurable infrared safety light curtain;

3, energy saving up to 40%;

4, position control accuracy 0.1mm;

5, pressure control accuracy 0.05t;

6, expandable hydraulic fixture power interface;

7, expandable assembly line automatic control interface;

8, equipped with manual or foot control.

equipment selection parameter table:

Project |

Unit |

SINEN-FCP-05T |

SINEN- FCP-10T |

SINEN- FCP-20T |

SINEN- FCP-40T |

rated pressure |

KN |

50 |

100 |

200 |

400 |

Travel |

MM |

200 |

240 |

280 |

320 |

Large Opening Height |

MM |

360 |

420 |

480 |

560 |

opening depth |

MM |

175 |

200 |

200 |

230 |

large downlink speed |

MM/S |

120 |

110 |

100 |

90 |

large uplink speed |

MM/S |

140 |

130 |

120 |

110 |

Workbench Size |

MM |

400 X350 |

450 X400 |

450 X400 |

500 X460 |

Motor Power |

KW |

2.2 |

3.7 |

5.5 |

7.5 |

Machine Tool Size |

MM |

1200X1100X1900 |

1250X1150X2000 |

1250X1150X2300 |

1350X1200X2450 |

Product Consulting

Related Products