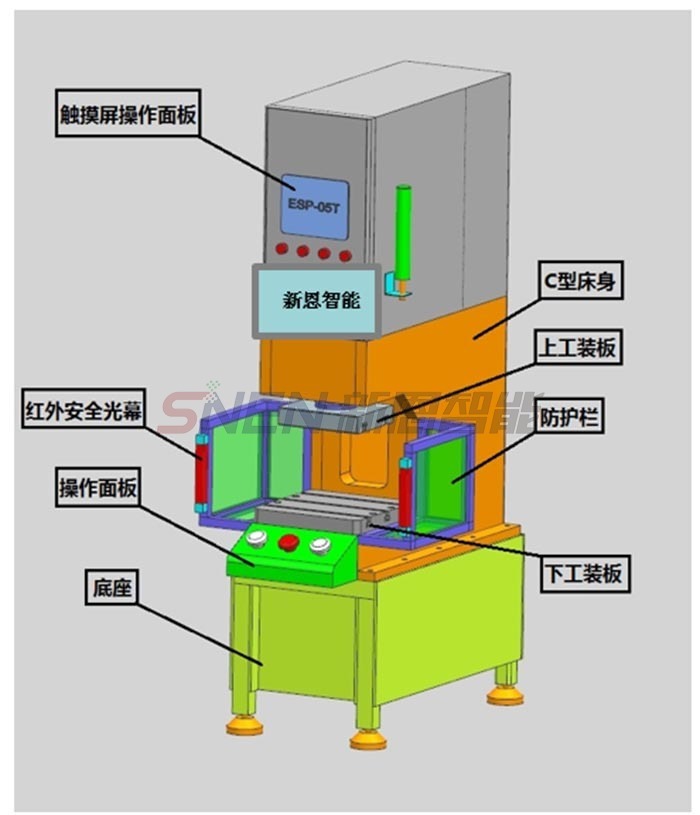

Intelligent servo press

We have been committed to intelligent test equipment system, intelligent AI Internet system, intelligent manufacturing production line in one, set design, production, sales of excellent service providers, to provide customers with one-stop industrial products-intelligent system solutions.

Classification:

Key words:

Intelligent Test Equipment System | Intelligent Manufacturing Equipment System

Product Description

Overview

Electric Servo Precision Press is powered by permanent magnet synchronous servo motor to drive high-strength precision ball screw. Servo full closed-loop control, compared with the existing ordinary press, has greatly improved accuracy, position repetitive control accuracy can reach 0.02mm; The force sensor and PLC algorithm control can accurately control the pressure in time. Compared with the traditional force sensor, the pressure stability is greatly improved, pressure precision control can reach 0.05t. Compared with traditional pneumatic and hydraulic presses,

is more environmentally friendly and safer, and can meet the requirements of equipment in dust-free workshops.

The whole process control can automatically determine whether the product is qualified at any stage of the operation, and remove the defective products in real time, thus realizing online quality control.

Functions and Features

1. Multi-speed precision press fitting can be set;

2. Online press fitting quality determination;

3. Press fitting curve display;

4. Multiple sets of press fitting program storage;

5. Pressure real-time monitoring and alarm;

6. Set force, position or displacement precision press fitting;

7. Reserved communication interface, can be put into the pipeline use.

equipment selection parameter table:

Project |

Unit |

SINEN-ESP-05T |

SINEN-ESP-10T |

Rated Pressure |

kN |

50 |

100 |

Travel |

mm |

200 |

240 |

Big opening height |

mm |

360 |

420 |

opening depth |

mm |

175 |

200 |

large downlink speed |

mm/s |

125 |

120 |

large uplink speed |

mm/s |

125 |

120 |

Workbench Size |

mm |

400X350 |

450X400 |

Motor Power |

kW |

7.5 |

10.0 |

Machine Size |

mm |

1000X800X2100 |

1000X850X2200 |

Product Consulting

Related Products